Industry 4.0 Overview

Introduction

Industrialization has started before decade. it saws the development of country. And this is the reason why every country focus on their infrastructure development. And every country keep improve their infrastructure development . So industrialization is not a new thing, but there is only one difference in industrialization and that is the way of working. Now techniques, machines, medium, people all has changed. Specially big change in manufacturing and production development companies.

Manufacturing industries now has been converting towards industry 4.0. they adoption new technology n their manufacturing process with the aim of grow their business fast. So there is one common question in the mind that what is Industry 4.0? then let’s understand it.

What is Industry 4.0?

Industry 4.0 is a revolution of manufacturing industry which facilitate machine-to-machine communication with minimum human efforts through networking of machines which facilitate automatic data transformation.

In simple words, Industry 4.0 is the transformation of manufacturing from traditionally to digital. Where most of the processes are automatic.

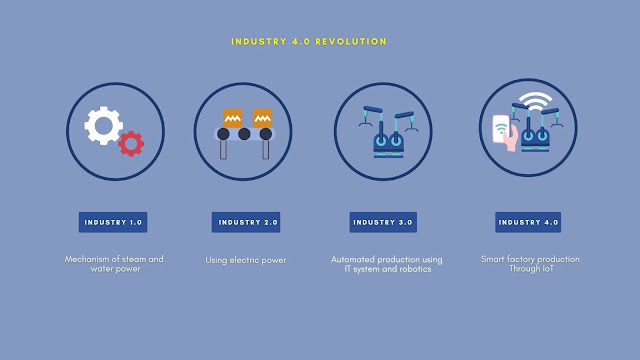

Take a look to industry 4.0 revolution for better understand.

Industrial Revolution from 1.0 to 4.0

Industry 1.0

Few decades ago, before 20th century Manufacturing Companies used manual way to produce their products with the help of people. The process and time both were time consuming and the efforts were very hard to produce one products. Companies use tools to make efforts easy but not very easy. Things were still difficult in manufacturing.

Industry 2.0

After 20th century , the world has entered in developing phase. And along with that, the manufacturing industries also entered that phase. That was the second industrial revolution phase. Where, companies stated to use of electricity in their manufacturing process to make thing quiet easy. And that help to increase efficiency in manufacturing. From that decade, the mass production concept were introduce in manufacturing industry.

Industry 3.0

The third industry revolution begins at slow pace. Because manufactures already featured their industries with advance electricity and computer systems. Although, there were human efforts require in manufacturing. But some big giants manufacturers notice the trend of manufacturing process and experienced technology and such big companies started to apply industry 4.0 in some activities.

Industry 4.0

And now from last few years, the fourth industry revolution has take place. That is known as an industry 4.0. where every manufacturer focus on technology where Internet of Things IoT help to make industry 4.0. this is the collaboration of Physical and Digital. Where everything is going to be automatic. Machinery has been guided by technology, manufacturer get real time data, easy interaction with manufacturers, partners, vendors, customers. In Industry 4.0, boost production of company with effective, in order, quick and on time .

Now you get it,

components need for foundation of industry 4.0

Big Data

Industry 4.0 concept based on automation of company. And every automation need large amount of data whether it is big or small automation. Because data need to enter in computer so that it reflect automatically. This is big challenge for manufacturing companies specially because there are production machines to make automatic. And also need to predict future. And data should be accurate to reflect. Too much data can create confusion. So research on big data is also important.

Cloud Computing

Cloud Computing is the fastest utility growing solution almost for all industry. Most of the businesses use cloud computing to make business more convenient for user or customers. Cloud computing is the delivery of computing services. With continuous advancements in technology, machine data and functionality will only continue to shift towards cloud solutions. The cloud allows for a much faster roll out of updates, performance models, and delivery options than standalone systems.

Internet of Things (IoT)

IoT is the key functionality of industry 4.0. IoT facilitate actual machine-to machine interaction without human involvement. IoT is a interrelated system of computing system and machinery, object and people that facilitate with unique identifier. And transfer data with the help of internet. The big example is automatic vehicles. Person can on car AC without entering in car with car remote key. Such technologies are connected with over the internet and transform data to any object.

Simulation

The simulations of systems allow assessment of various scenarios. Once the scenarios are assessed, cost effective solutions can be developed, tested and implemented much quicker leading to reduced cost and time to market.

Autonomous robots

Automatic robots are programmed once and then operate by them self according to command. Manufacturing company need autonomous robots to make industry 4.0. autonomous robots are power on concept on IoT. Materials transform and other task in company floor are perform via Autonomous Mobile Robot.

Augmented Reality

Augmented Reality use to provide real time information for better interactive solution with electronic system. For example, alignment of car tyres which reflect in other electronic device in a 3D view for better judgment. And operator can easily perform alignment process within a minute.

Cyber Security

When things come to make devices automatic via cloud computing and IoT, the security factor is also very important. Because security make technology more reliable and enable a truly successful implementation in a modern way.

System Integration

Most of the systems are highly automated. So system integration makes communication easy between machines and objects. This may involve common language for data exchange.

Benefits of Industry 4.0

Reduce Downtime in Production Process

Problem in manufacturing machines is a major problem and for that, company has to stop whole production process because identifying problem nature is important to resolve and it takes too much time. But in industry 4.0, this issue can be solve with the help of ANDON system which facilitate quick identification of problem in particular area in machine and because of that, It doesn't take long to find a problem. And issue can be solve within a time.

Increase production capacity

In automation, chance of errors is very low and sometime no chance of errors. And if problem arise, it quickly recognized and solve within a few minutes. Such things directly affect the production flow and capacity. If everything is alright, the production capacity can be increase.

Real time data.

Counting total unit in production is quite difficult job. There can be miscounting in human counting, but if machine are automated then there can be accurate count of units of production. And defective product automatically reject before dispatch and these data also reflect on computer or any LED Display Board.

Improve Demand and Supply

Cloud and IoT based inventory management system can improve better communication with supplier. That's How, Company can manage demand and supply flow of products.

0 Comments